219

3826

Racing in the blood! The Richard Mille RM050 and Lotus F1

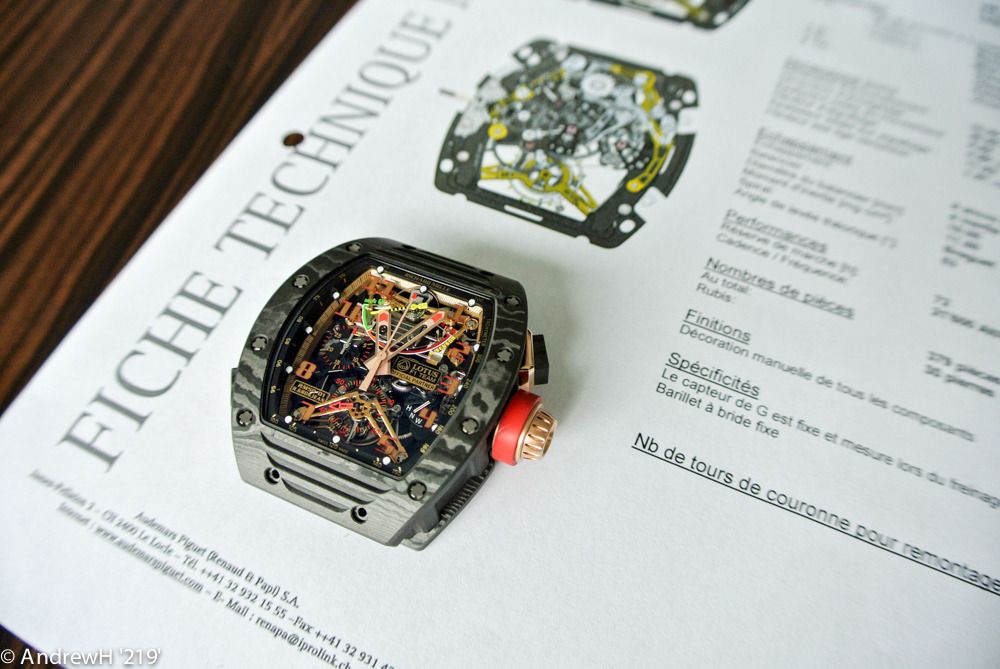

[A racing machine on the wrist: the RM050 Lotus Romain Grosjean]

For the man, and the watch brand, that more than any other had taken Formula 1 Grand Prix racing and distilled it into watchmaking, Richard Mille now had his name on the front of a F1 car. In Formula 1 racing, where material science fuses with the heat of competition, car and watch are not only made from the same materials, the watch itself imparts that same spirit of engineering and materials at the limit. For Richard, his watches were always designed and manufactured to be: “A Racing Machine on the Wrist”! In 2013 he had gone into partnership with Lotus F1; and perhaps more than any other F1 team, it was a fitting union. Lotus F1 was founded by an Englishman – Colin Chapman - who through innovation and design had revolutionised Formula 1 racing in the same way Richard’s watches had in horology. Across time, two men with “racing in their blood” had the same philosophies at their heart: innovation, design, and technology.

The screen on my phone radiated with a new call. Caller ID: “Richard Mille”! Richard was on the line. “Bonjour Andrew! How are you?” boomed the voice on pressing the accept button. “You sent me some questions about Lotus – yes? So …. I am phoning you to talk about them!” This was something of a surprise. Usually Richard e-mails responses; so if he is phoning; it is usually something that he wishes to be more effusive about than words on an e-mail can convey. We are chatting about cars and design aesthetics. “So Richard, Lotus – why Lotus?” I ask.

Colin Chapman and Lotus: “Simplify, and then add lightness!”

[Colin Chapman at the wheel of the innovative Lotus 49]

Richard always claimed he suffered an “Enzo Ferrari syndrome”: not an engineer in his chosen field, but a wish to control creation and concept. But to my mind, Richard was always closer in approach, spirit, and knowledge to Colin Chapman (Founder of Lotus Cars: the predecessor of the current Lotus F1): an innovator; someone who took what was known and turned it around. Like Colin, Richard used his knowledge from his work, his hobbies, and his passion to create Richard Mille Watches S.A.. Like Richard, Colin Chapman used his knowledge from his work, his hobbies, and his passion and formed Lotus Cars. Both men entered their respective areas with new thought, new design, new materials, and turned accepted thinking around. There are some interesting parallels between the two men, including the speed at which their respective companies succeeded, and the way their new direction in their chosen industry led to a paradigm shift in thought and application.

[Jim Clark at the wheel of the Lotus 49 in 1968]

Colin Chapman studied structural engineering at University College London, learned to fly with the University of London Air Squadron, and acquired knowledge about the different properties of metals when he joined the British Aluminium Company. In 1952 Colin Chapman founded Lotus Cars. Initially Lotus Cars’ was run with friends and enthusiasts. But what made the difference for Lotus Cars, in the development and technical advances of racing machines, was Chapman’s knowledge of the latest aeronautical engineering techniques. Even now, Formula 1 cars owe some of their current design to innovations that Chapman introduced. Chapman became famous for not only designs, but in the use of lightweight material. His guiding philosophy to car design was: "Adding power makes you faster on the straights. Subtracting weight makes you faster everywhere".

[Jim Clark at the wheel of the Lotus 25]

Lotus cars became renowned for innovative design, lightweight construction, and fine handling instead of ‘brute force’ engineering that would concentrate on horsepower and spring rates (setting the suspension on the car for cornering). It took just over a decade for Colin Chapman and Lotus Cars to become established in winning the Formula 1 constructor’s championship (in 1963). The lead driver – Jim Clark – was also crowned drivers world champion. Chapman had claimed both titles with the Lotus 25. It was a revolutionary design; the first fully stressed monocoque chassis to appear in F1. The original sketches for the car were made on napkins! The monocoque, a technique borrowed from the aircraft industry, made the car more rigid and structurally stronger than typical F1 cars of the period. The Lotus 25 was three times stiffer than the previous generation car, while the chassis weighed only half as much. The car also was extremely low and narrow the driver reclined sharply behind the wheel leading to the nickname 'The Bathtub'; the reclined position also allowed a more aerodynamic profile.

[The importance of the engine as a ‘stressed member’ of the car: all cladding and structure have been removed from the engine. The engine now supports the rear suspension].

With the Lotus 49, which Richard Mille admitted was one of the cars that had influenced his own watch designs, Chapman went one step further and successfully introduced the engine as a ‘stressed member’ in the car. The antecedent of which was Chapman, who in 1966 persuaded the Ford Motor Company to sponsor Cosworth's development of what would become the DFV race engine. The Cosworth DFV was specifically designed as a stressed member engine; acting also as an active structural element of the chassis to transmit forces and torque, rather than being passively contained by the chassis with anti-vibration mounts. Automotive engineers use the method for weight reduction and mass centralization in vehicles. Chapman was not the first to try such a design, but he was so successful in his implementation that others copied him thereafter. Chapman had defined the modern race machine for the track.

[Emerson Fittipaldi at the wheel of the Lotus 72: the first Lotus car to be decked-out in the black and gold livery]

Richard took this idea and applied it to his watch designs from day one. He was influenced by the way that car and engine were designed together; the way the engine (movement) and chassis (case) were designed as an integrated whole and that design mantra continues today with the RM050-Lotus. Despite lightweight materials being used in the watch construction, the watch feels very rigid; as any Formula 1 car should.

Richard Mille and Richard Mille Watches S.A. “A Racing Machine on the Wrist”.

[Richard Mille’s latest Formula 1 racing machine for the wrist: the RM050 Lotus Romain Grosjean]

After an education at business school, and years in the watch industry (working for firms as diverse as Seiko and Mauboussin), Richard decided it was time to form his own watch company. With a few friends and colleagues, in 1998, Richard decided to introduce his own line of watches. Not being one to hold back, Richard started at the very zenith of possibilities. The break came at a time when Richard was working with Fabrice Deschenel at AP Renaud & Papi on the application of three-dimensional movements for Mauboussin jewellery pieces with a tourbillon. The approach was new, but despite the obvious visual impact, Richard had another idea where the three dimensional aspect to the movement would work: a modern approach based on modern ideas. A racing machine on the wrist!

An industry veteran, good friend and colleague in Dominique Guernat, friends and colleagues from the industry at AP Renaud & Papi, and a few retailers who would help with promotion, and Richard Mille Watches S.A. was off to the races! The initial watch designs were sketched by Richard and then consolidated with the CAD programs. The movements were to be supplied by AP Renaud & Papi; the case manufacture would be Donze Baum. Richard would design it all and put case and movement together. The guiding philosophy: technique and new materials. The very same materials and techniques as used on Formula 1 cars; the very same ideas sketched out on paper (or napkins if need be).

Richard had defined the modern watch. In so doing, he has also defined a new luxury. Luxury watches based on esoteric materials where the value was in learning about the new material and finishing. A watch could be unique, rare, valued for the skill and mechanics it embodied without a single gram of precious metals. Richard was always concerned that the internal structural rigidity of his watches was paramount, irrespective of the new materials or new techniques being used. The watch had to have the same feel and philosophy as a racing machine for the track.

In about a decade, Richard Mille Watches S.A. went from producing just 17 examples of his first watch: the RM001, to an annual production (across a range of watches) of around 2000 watches and along the way winning most watch awards in the book. The list of examples where new materials and technique triumphed to stunning effect was: RM006 - creating a carbon nanofibre baseplate; RM009 - using ALUSIC for a complex case {aluminium/silicon alloy} RM012 - the use of titanium tubular structures for the baseplate; RM021 - orthorhombic titanium aluminide baseplate {Orthorhombic titanium aluminides are a new class of titanium-aluminide alloys); RM050 - the NTPT carbon case {North Thin Ply Technology) describes a proprietary process that creates extremely thin pre-impregnated fibres tapes that are layered in particular patterns.

Lotus F1 Racing

At last – just over a decade after formation, Richard Mille’s name was on a team F1 car! With Richard’s name now on the nose of a Formula 1 car, it was time to take a look at the techniques of manufacture, and how closely a RM watch uses the same methods or knowledge. The short answer to all this is yes! But more than I surmised and more than people realize. Richard Mille’s by-line has always been: “A Racing Machine On The Wrist.” Although parallels have been drawn in the past between the watches and the racing cars, this is the first time that someone with knowledge of Richard’s watches has also been allowed to talk to a Formula 1 team about the details of manufacture and technique. It is the very essence of the Richard Mille watch. As I learned from Lotus F1, as far as Richard Mille watches are concerned, the similarity between cars and watches is perhaps no longer based on the size of hammer used (as George Daniels once remarked), but on the similarity in technology embodied in your material manufacture, and the complexity of your CNC machine!

[The Lotus F1 car in the team garage. I have seen doctor’s surgeries with more dirt! Although it does have the same cleanliness factor as a Swiss watchmaking room!]

Racing cars, especially Formula 1, in this day and age are a technology driven machine. The shape of the car relies on a mix of computer design, whatever rules have been instigated for that season, and design work with CAD and other specialized software. Computer design is now aided by the terabytes of real time data that are fed from sensors on the car. Before such electronic sensory perception was possible, cars were the basis of flights of the imagination in the designers mind. A piece of paper, a pencil, a sketch and a new form of aerodynamic racing machinery had been born.

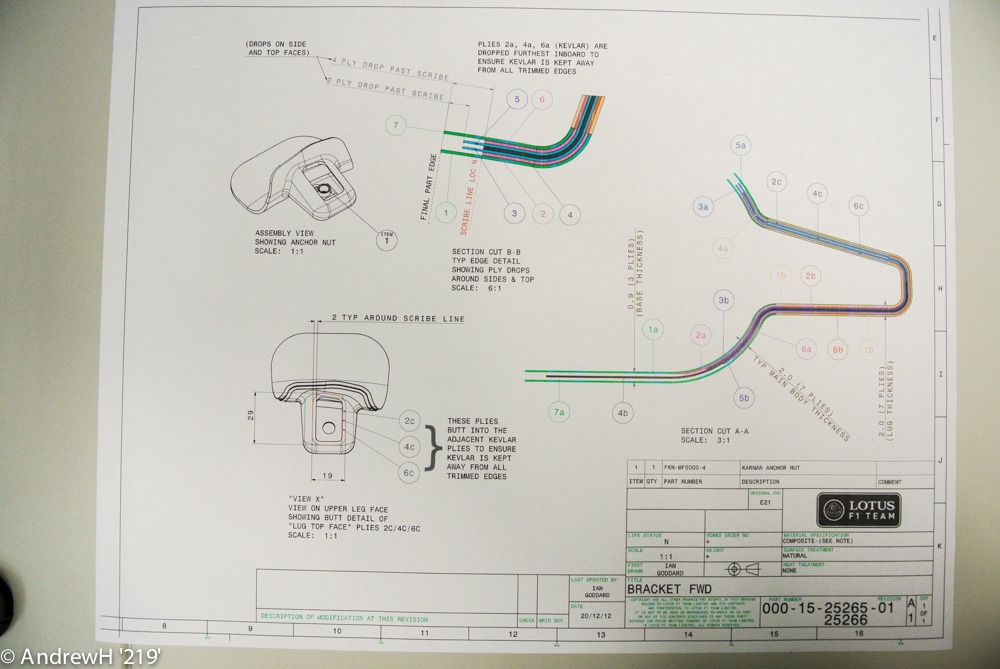

[Every component of the modern F1 car starts out being designed on the computer. The colouring on the diagram: for a lowly bracket, indicates the density, depth, and direction of the carbon fibre weave in manufacture. These diagrams are then passed down to the carbon fibre production area]

[The bracket from the design above]

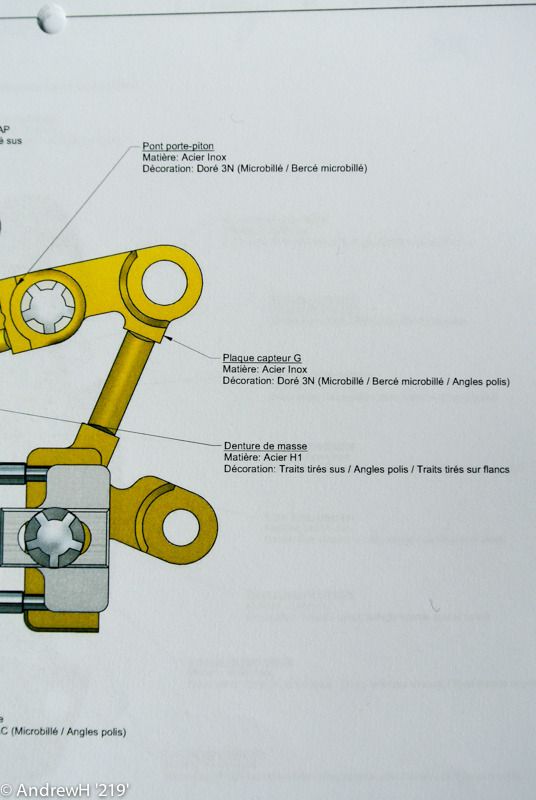

[Each and every element of the Richard Mille watch receives the same treatment. Design down to the exact composition and measurement of every component: each screw, the depth and alignment of carbon fibre weave, the dimensions of every element.]

Today, a Formula 1 car is in a state of perpetual flux. What exists one week will not necessarily exist in two weeks’ time (for the next race). Real time track and wind tunnel data are analysed and dependent on the type of track for the next race, new forms for the ducts and panels will be manufactured. As most of the car is manufactured out of carbon fibre, Formula 1 teams have become experts in its manufacture and use. Only by seeing the manufacture and use can you appreciate how closely Richard’s own manufacture and use of carbon fibre mirrors the racing machines that duel it out on the Formula 1 circuits throughout the year.

[Every component is specifically designed for each race: including the suspension struts, which are made from carbon fibre to required strength and tensile flexibility]

In Formula 1 every component on the car has to be exact. Just as in watchmaking; exact to the very finest of dimension, weight, and tolerances. From talking with the designers and engineers at Lotus, it turns out that carbon fibre is not just a case of getting your layers of carbon fibre material and resin, and simply pasting it together. There is more to the science and art than that. First, there are different forms of the carbon fibre weave. Different textures and different depths of material will be used for different purposes. Further, the actual direction of the weave and how it is layered matters to the integral strength, flexibility, and durability of the part. Even the smallest of parts within the car that is made from carbon fibre has to be designed and manufactured exactly.

[The depth and breadth of the carbon fibre weave used in the parts for the Lotus F1 car]

From the very beginning, each part from the lowly bracket up to a complete wing is designed with dedicated software that works out the direction of carbon fibre weave and the density of the material. Manufacture is then checked by weight; each component must be within +/- 2% of the specified weight and the density and consistency of the resin is checked for defects by radio imaging. Finishing is by hand. Although this is an industrial process, and the component is made using an exact system for manufacture, the actual finishing is completed by hand to ensure that each and every component of the car fits and works together perfectly. I heard frequently from the designers and engineers at Lotus: “Formula 1 is a hand skilled industry”. In total, for one team, this hand skilled industry has to know how to use 32 different carbon fibre materials and manufacture over 20,000 carbon components in a season. It is a perpetual limited production!

[The process of producing each and every part: every part of the whole car is moulded and sculptured using the blue material. Before lamination, each part is hand finished. The part is then laminated (top right). The carbon fibre is then produced to the specification of the design and finished (centre and bottom left)]

The limited production (which was compared to a bespoke practice by the Lotus designers and engineers) starts with the design of the car itself. Once the car has been designed, the parts are isolated to build each individually. Initially, the whole car is designed and constructed as a ‘blue’ mould: the blue mould parts are initially cut by machine, but the final finishing is by hand. The mould is then laminated. The density of the material is indicated by colour and the designs designate everything: from the orientation of the carbon fibres in the material to the optimisation of the material and resin at that point. While laminates and composites materials look easy, it is anything but. Composites require detailed knowledge of their properties in use, and how various disparate composites will work together. Often, composites will be combined if there is a need for strength at one particular part. For example, where structural rigidity is required a combination of both carbon fibre and orthorhombic titanium aluminide, or orthorhombic Kevlar might be used. The materials are adhered together. There is a need to consider what is required at each exact point on the car.

[The orthorhombic titanium can be produced to specification and order. It is then sandwiched between the carbon fibres which is also produced as other parts to the required dimensions]

Despite the need to reduce weight and increase rigidity as far as possible, there are some elements (apart from the engine and brake units) that still require metallic form. If a physical mounting is required, or where something intricate is required for the car, there is still the need to use metal for the known tolerances and strength in the material. In such instances, titanium is used and then bolted onto the carbon fibre parts. I asked the Lotus engineers why other metals were not used; some of the more esoteric forms such as Alusic (used in the RM009). Surprisingly, despite the obvious advantages, such metals are no longer allowed in the cars. While such metals are a definite advantage, they are also very expensive. The Lotus engineer smiled: allowing the use of the esoteric alloys would play into the hands of the larger and well-funded teams. Such esoteric metals are (as Richard found out) extremely expensive to manufacture and to shape to the required dimensions. The RM009, introduced in 2006, is a product of Formula 1 at the time, when such materials were permitted in cars. Richard’s use of materials in his watches has mirrored the sport. At the current time, the cars are manufactured from known materials such as carbon fibre and titanium, where the technologies are known and reasonably readily available to all teams on an equal basis. Richard’s watches concentrate on carbon fibre in various forms, with titanium inserts for structural rigidity and to help fasten the movement inside the case. And this is precisely the approach for the production of Formula 1 cars at the current time.

[Where moving parts need known tolerances and strength, titanium metal parts are fixed to the carbon. In this instance with bolts]

[For the exhaust manifold, carbon fibre elements are glued to the metal parts. The glue is similar to that formerly used on the space shuttle]

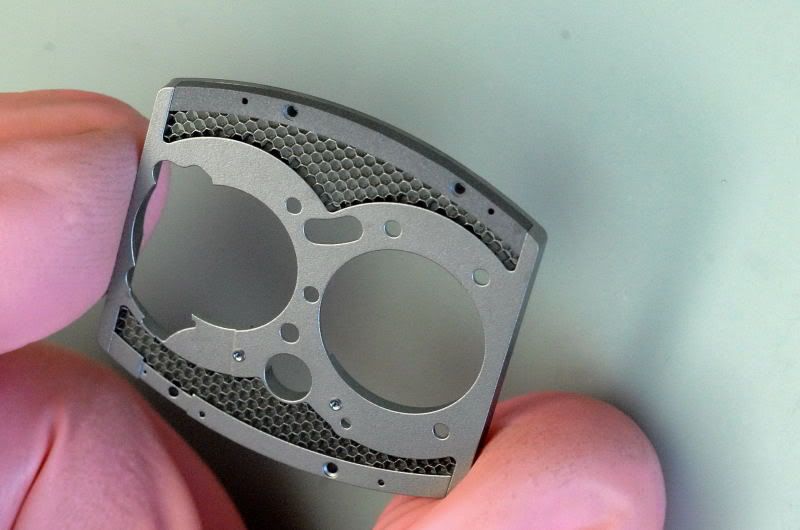

The use of such materials and technology in Richard’s watches is obvious. Richard Mille was the front-runner in producing watches that used carbon in various forms since the RM006 was fitted with a carbon nanofibre baseplate (with a titanium case). The RM009 was a reflection of known metals technology within Formula 1 at the time it was made. The RM021, with its orthorhombic titanium aluminide baseplate was introduced the same year that Formula 1 cars. Since then, and leading up to the RM050 Lotus watch, Richard has continued to pursue the use of new materials, to understand their properties, and the machining and hand finishing that they require.

[Baseplate to the RM021: orthorhombic titanium aluminide}

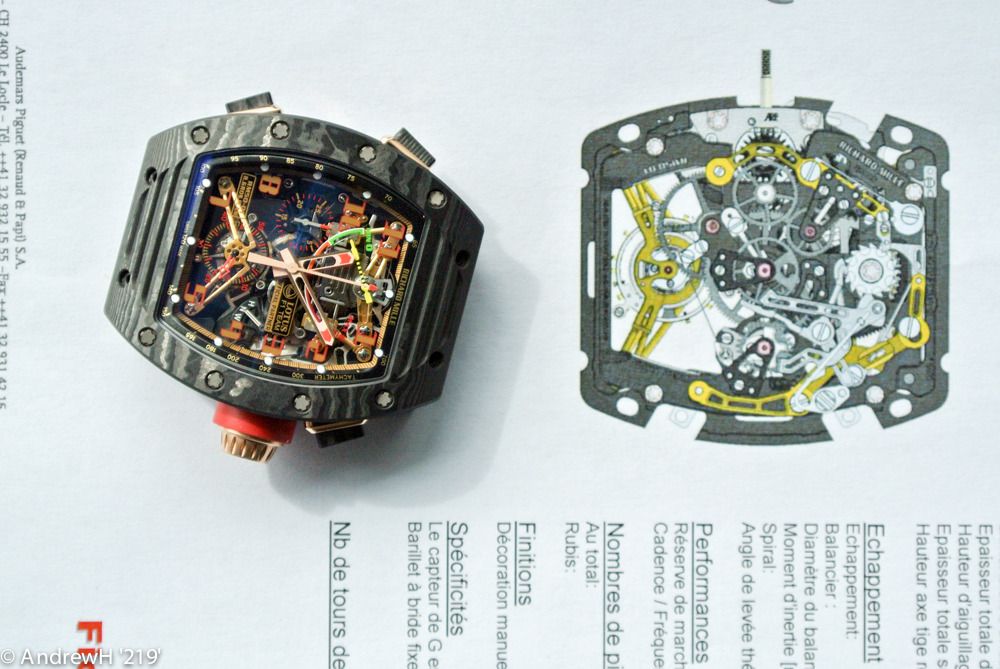

Romain Grosjean and the RM050 Lotus

[Romain Grosjean at the Lotus F1 Headquarters]

The RM050 Lotus is Richard’s latest watch connected to the Formula 1 racing world. With a new brand ambassador in the form of Romain Grosjean, and with both a driver and car with his name on it, Richard Mille is now firmly involved in the world of Formula 1 racing. As part of the visit to Lotus there was a chance to talk to Romain about racing and Richard Mille watches. Although new to the Lotus team in 2013, Romain has a long history in motor sport, having become addicted to the sport when he went to see his father. However, his passion remained unfulfilled until his grades at school improved. Under such an incentive scheme, both school grades improved and Romain was allowed to take up motor racing. He went through the usual route of go-karting, lower formula racing, GT and LMP class racing before arriving at Formula 1. His seat at Lotus is actually the second time in Formula 1. Initially he joined the Renault team in 2009, but left after one season. Being a joint Swiss native, I had to ask if he had ever thought of going into the watch industry. But no, that was not where the young Romain’s ambitions were to lie. He went into the other Swiss industry: banking! For two and a half years (until he joined Renault) he worked in the banking industry at Baring Brothers, wore a suit and tie, and went to work at 7am every morning. He admitted that although not his chosen career path, it was good discipline. In his spare time he was still racing in the FIA GT1 World Championship driving a Ford GT1 for the Matech Competition team. Once again, Romain worked his way through the lower formula racing before being invited to join Lotus Team Formula 1 team in 2012.

Romain became a brand ambassador for Richard Mille in 2014. The RM050 Lotus watch was Romain’s first foray into watch design with Richard. The two met at the beginning of the year, and as always with Richard, the decision was instinctive and immediate. From that moment on, Romain Grosjean was part of the Richard Mille family. Work started almost immediately on the RM050 Lotus watch. As with all Richard Mille sporting ambassadors, Romain Grosjean is required to wear his watch while racing. To emphasize the point, Romain wears his watch with a yellow strap on top of the drivers’ overalls. I asked Romain if, driving a predominantly carbon car, and wearing a predominantly carbon watch, there was the same intrinsic feel between the two. Romain enthusiastically replied: “The watches have the same essence as the cars because they use the same components. The watch and car have the same technology behind them. It is getting to the highest level of what you can do with a watch; the same as we do in a car. The watch has the essence of racing.”

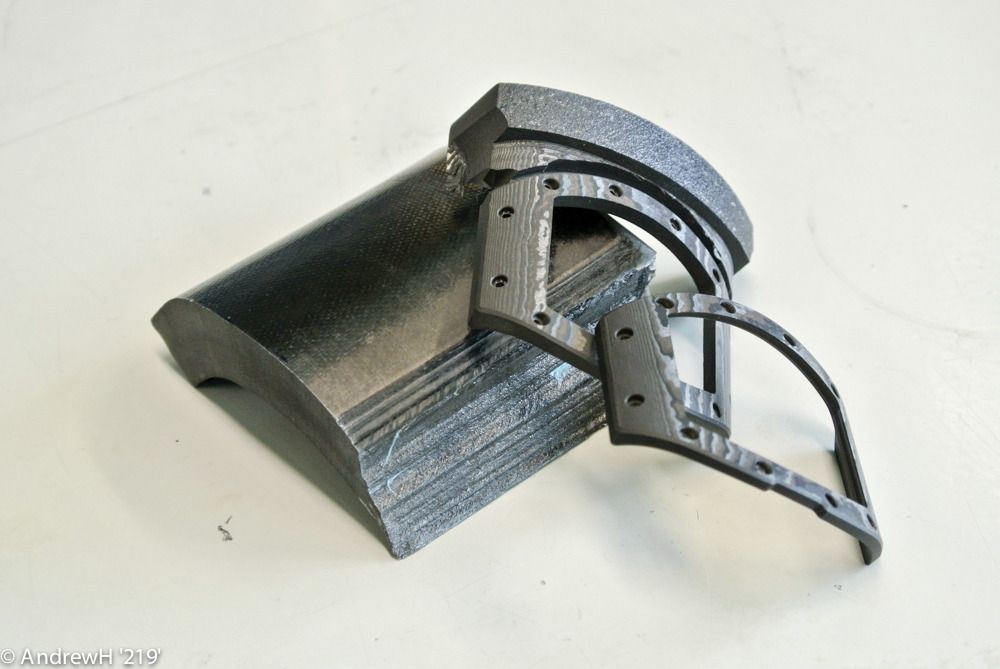

[The basic block of NTPT carbon and the crude machined parts for the case. Note how the thin leaves of carbon fibre are initially shaped with the same curvature as the case]

The RM050 Lotus watch is the first time Richard has produced a watch as an official team sponsor for Formula 1. In keeping with Romain’s thoughts, and the production methods behind the car, the watch has the same production techniques. For the NTPT carbon case (a Swiss technology), the leaves of carbon fibre are moulded in the same basic curvature shape as the RM case. Extremely thin carbon filaments are separated from larger carbon fibres until they are a maximum of 30 microns (three hundredths of a millimetre) thick, and then these are woven with the support or some resin, with each layer being turned 45 degrees in relation to the layer below. Despite this, the exactness of the curved NTPT block, and the thinness of the carbon fibre layers, the case’s wood-grain appearance comes’ from the fact that the Richard Mille case is machined to tolerances of a hundredth of a millimetre.

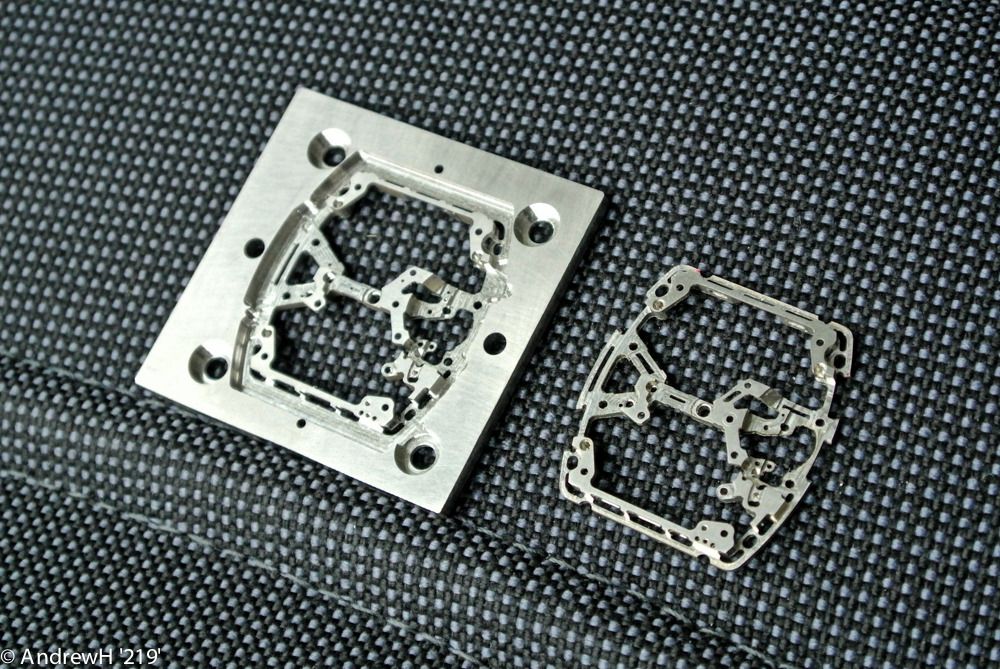

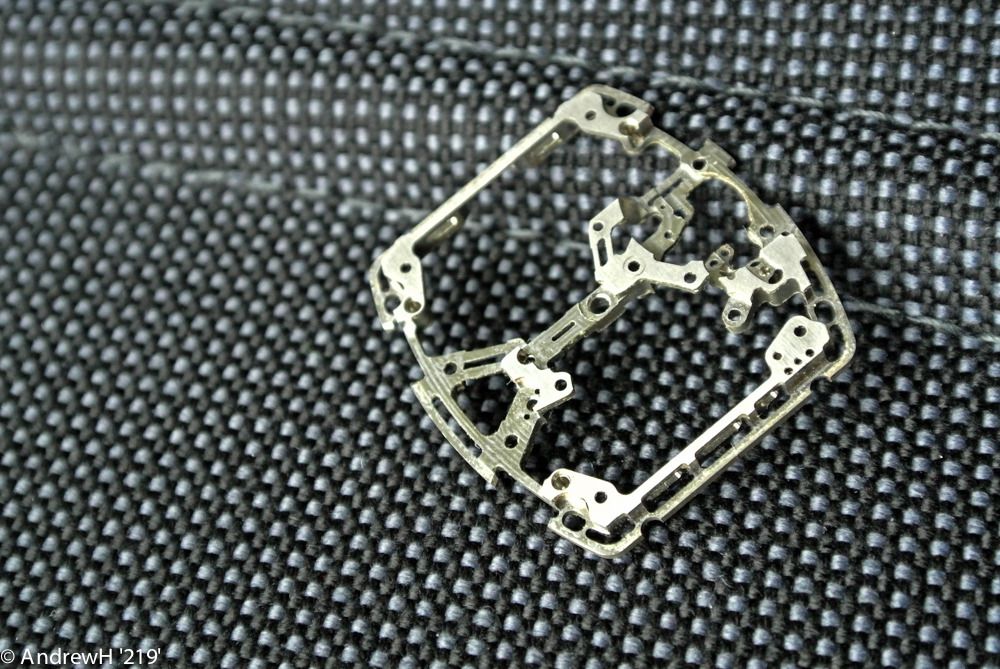

[The titanium baseplate for the RM050: carbon plates and the various components for the watch are then fastened to this plate. Carbon could not be used because of the form and complexity of the pattern on the baseplate and the need for rigidity]

Within the NTPT case, the watch’s baseplate is a titanium insert (chassis) that holds the elements of the watch. At the top end of the watch are the winding-barrels, and the micro-mechanism to indicate the g-force; at the base, the regulating mechanism (in this case a tourbillon escapement). Between the winding barrels and the escapement are the drive train and the chronograph. It truly is a watch as a representation of the Formula 1 car! In this instance, the black carbon and the gold plated movement bridges, taken from the colour scheme of the Lotus F1 car, lend themselves to the Richard Mille aesthetic. The black and gold colouring for the Lotus F1 car has become iconic and instantly recognisable; it is their insignia. It was another Colin Chapman innovation: advertising from sponsors on the racing car. It changed the colour of Lotus F1 cars from green and yellow (green being the British racing colour), via red and white (for Gold Leaf Tobacco), to the now instantly recognizable black and gold (originally for John Player Special cigarettes).

Epilogue

[Richard Mille’s Lotus 49. In some of the first tobacco sponsored racing livery: Gold Leaf Tobacco]

I was back listening to Richard on the phone. “So you see I took inspiration from Formula 1 cars. Have you seen the Lotus 49?” was the question. I had to admit that I had not. “It was incredible!” continues Richard, “It was path-breaking; the weight reduction, the handling, as a design it was so new! It won because of the new materials and the new way engine and chassis were designed together to improve rigidity and reduce weight!” “Did you ever meet Colin Chapman?” I ask. “No, but I know his son! He’s in charge of the Lotus historic racing club!”

When I was a boy, (which was roughly same time as when Richard was in his formative youth) the “all conquering” Formula 1 team was Lotus: the John Player Special (JPS) Lotus 72 with Emerson Fittipaldi as the lead driver. It was the 1970’s and an impressionable young boy could not help to be captivated by the speed, the glamour, and the daring of the cars and drivers that were Formula 1. My prize possession at the time was a metal model Lotus JPS 72. I even kept it in the box!

Formula 1 was then, as it is now, the sense of taking man and machine to the limits of the laws of physics and human capability. It is at the heart of the appeal of F1. The best drivers with the most advanced, challenging and fastest cars that man and science can produce (in F1’s case within the limits imposed on them). With Richard’s watches, that essence, that spirit, that passion is now imbued in a racing machine on the wrist!

© Andrew H, 2015. This message has been edited by 219 on 2015-08-22 07:09:36 This message has been edited by 219 on 2015-08-22 07:11:54

Racing in the blood! The Richard Mille RM050 and Lotus F1

RM is a great actor of the technical fields in which cars and watches are involved

Thanks Mark. Agreed, it is not to everyone's taste, but where as

Your article had an excellent influence of Romain Grosjean!

Amazing result with limited budget and lawsuits

Thanks! I would love to claim credit.... but

Richard Mille, perhaps more than any watch brand, has One Encompassing Vision

Thanks Melvyn - racing cars has always been Richard's driving

Sadly, MTF

I don't need the founder or his descendants to still run the company

I agree...

The current Lotus team

I would be a little surprised to see the team turn

hopefully

I seem to remember in...

Indeed! Great photo...

Thank you Andrew for this truly extensive detailed article

I don't have your answer Anthony

I am not sure about the forged carbon...

CFRP

Thanks for sharing your knowledge BDLJ

WOW! Impressive. But I thought that NTPT was not

You're not mistaken!

This why I love this site.....

Now this is what you cal back stage pass.

Thanks Bill. Admittedly I was very lucky and

What a great in-depth behind the scenes look at the engineering art of Lotus F1 and Richard Mille