Two Meisters of SEIKO - Part I

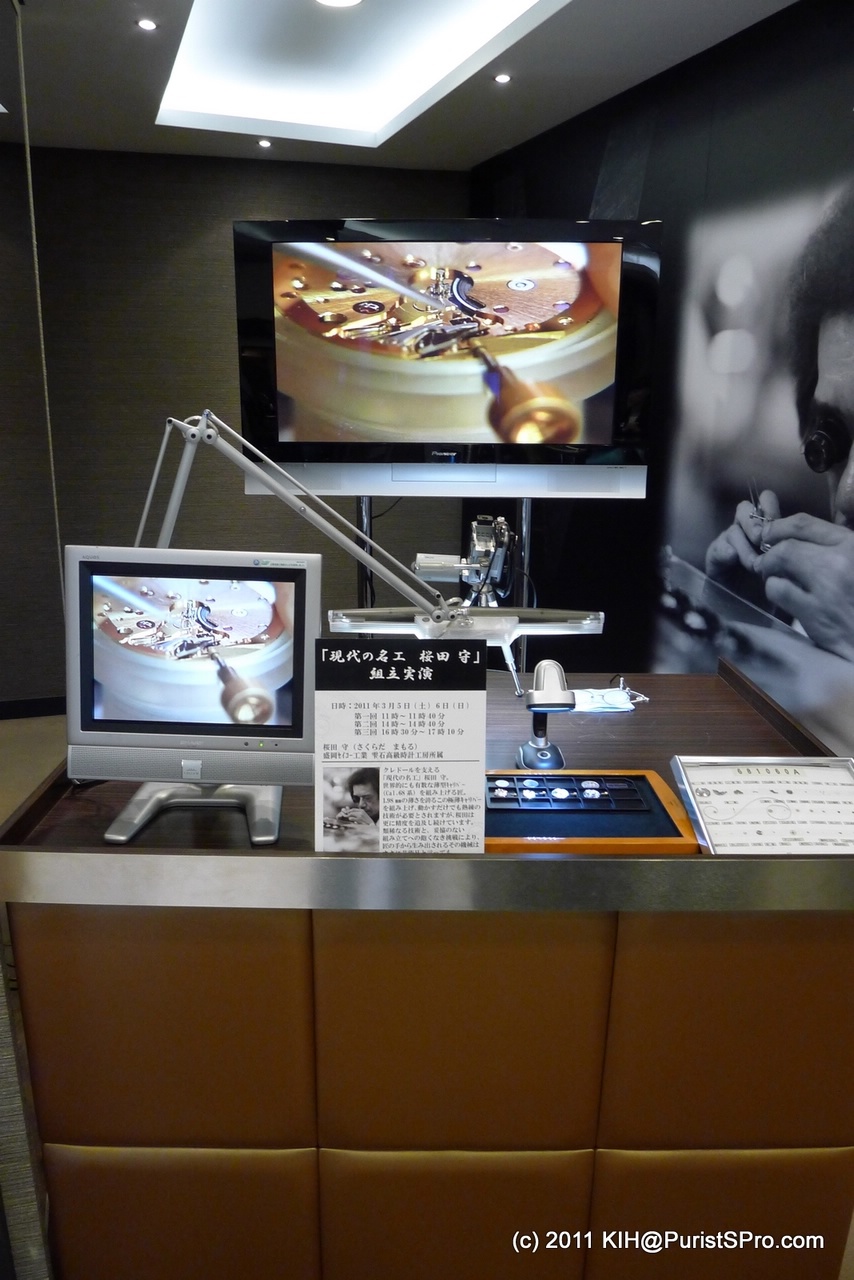

For all SEIKO fans - The Two Meisters of SEIKO Shizukuishi Watch Studio demonstrated their technique/skill at an event.

One weekend last month, a week before the quake, there was an event by SEIKO at a department store in Tokyo where SEIKO’s TWO legendary Meisters – Mr. Mamoru Sakurada (watchmaker) and Mr. Kiyoshi Terui (engraver) – demonstrated their works. They have both been chosen as “Contemporary Master Craftsmen” of Japan and also been awarded “Yellow Ribbon Medal” from the government (presented by the Emperor: as of today, there are THREE more recipients in SEIKO group alone).

(FYI – Department Stores here today are major distribution channel for the hi-end watch brands including but not limited to Patek, Lange, Cartier, etc.)

I was so excited to see the demonstration because I missed them both at my visit to the SEIKO Shizukuishi Watch Studio last month (see here:home.watchprosite.com). Mitamura-san of SII told me about this event and I could finally meet them.

(Note: As I reported while ago, Morioka SEIKO and Shizukuishi Watch Studio did not suffer much damage - fortunately it is located inland of Iwate prefecture)

Two gentlemen are so nice, friendly and patient to explain and answer questions. They seemed to be really enjoying what they do and I hope you enjoy reading this report. My apology in advance for poor quality of the photo because many of them were screen capture from the video (the camera was my Lumix P&S, though)

I divide the article in two parts - Part I is about Mr. Sakurada's movement assembling, and Part II which I will publish next week is about Mr. Terui's engraving.

1. Master watchmaker – Mr. Mamoru Sakurada

Mr. Sakurada has been with SEIKO for 45 years (joined SEIKO in 1965) and has been responsible for assembling and adjusting the Ultra Thin series movement 68XX. Cal. 68XX is 1.98mm thin, which is almost as thin as and tad smaller than 500 Yen (about US$6 these days) coin, and still is going strong in the Credor Ultra Thin line.

This 68 series caliber was introduced in 1969 - a year after SEIKO achieved the highest ever score in the Geneva competition and was awarded the "best mechanical wrist chronometer" - to further pursue the higher standard craftsman skills and aesthetics, in addition to accuracy/ precision. But as I reported last time, SEIKO sort of stopped manufacturing mechanical movement after the Big wave of "quartz" changed the horology scene completely. As proven by the fact that it has been in production for such a long time, the movement is robust. The spec says the accuracy is +25/-15 sec per day.

Mr. Sakurada, in 1990, took leadership and initiative to revive the mechanical movement and has been responsible for 68 series ever since.

These are a few of today's models which has 68 series caliber inside - Credor line.

He demonstrated the assembly of this ultra thin movement. At the beginning, I was told that although the number of the parts is about 120 and less than average mechanical movements out there, this movement won’t work by “just” assembling. It requires lots of manual adjustment in the process of assembly, thus requires proficiency and experience.

(Please note that the demonstration of assembly was done in just an hour, which is unrealistic and must have skipped many steps)

The base – made with brass. This 6899 is for skeleton model and will have engraved parts on and on (engraving is by Mr. Terui and his team), but ironically that makes the assembly a bit more difficult that it already is – stay tuned. This caliber has 26 jewels.

First, he puts 6 wheels including the escape wheel on the base, knocking the assembly stand to have the gears “in”.

Then, he put the beautifully engraved train wheel bridge on and above the wheels. And three blued steel screws are tightened for the bridge. The screws are in-house made in Shizukuishi and seven screws in total for this caliber are chosen so that they are all the same tone/ color.

BUT, this is in reality the first tricky part. This bridge is rarely or never completely flat – due to many factors including the engraving process. For the wheels to rotate smoothly and keep the movement thin, the tolerance of the “error” is 1/100mm to 3/100mm. The master first checks the actual gap or play of the wheel and the bridge/ ruby. His fingers feel and “measure” whether it is within 3/100mm.

And if NOT, then he has to tighten or untighten the bushing around the ruby from either side by tiny amount to adjust. For normal watch, the tolerance is more than 5/100mm and bridge and wheels should fit instantly, but this is so thin it doesn't work that way.

He also has to check the flatness of this thin bridge because by the time it reaches him, a lot have already been done to it – cut and shave, bushing pushed in, and particularly for this 6899, the engraving. He checks the flatness by holding one side on the flat metal stand and press another side tip, and he “knows” how much it is up or down. Then he, by hand, with very sensitive touch, bends or unbend the part. That is only done by experience.

Video of how he "adjusts" the flatness of the bridge.

Pretty amazing, huh? Totally by hand (or finger) and he "feels" the 1/100mm difference.

Now he goes on to put the barrel in which the main spring is in. Note that one side of the barrel is left open to save the thickness of the movement – inside the barrel can be seen from the dial side. Three rubies works to “hold” the spring inside the barrel.

Putting on the barrel bridge, fixed with screws, click is put in place, and then put the ratchet wheel on the barrel mechanism.

Click is put on.

Anchor or pallet fork is put In place (so the barrel/ spring actually winds and accumulate power).

Now the pallet bridge is put in.

The pallet bridge in this model is fixed with only one screw due to the space. But the bridge is bent (by hand) slightly – approx. 3/100mm - and the other side is held down and stuck by the friction.

Put the smooth balance wheel mechanism in. Before this parts arrives here, the balance must be manually adjusted. How? This is the next tricky part. The smooth balance wheel is adjusted by putting the hole or holes in or shaving the surface of the rim of the wheel. He finds out where to shave or put the hole by measuring which position generates substantial delay (delay means “heavy” . He measure the movement with various positions and disassemble until the balance is right. It obviously takes a long time to really make this movement ready for casing.

. He measure the movement with various positions and disassemble until the balance is right. It obviously takes a long time to really make this movement ready for casing.

Waiting is many trial and error of balancing the balance wheel right.

Assemble, dissemble many times until everything gets right.

Now it is ready to put the hour hand, then minute hand at exactly 12 o’clock, put in crown, put into the case…. All done in an hour, but it normally takes a full day at best.

This was a very interesting demonstration by the master of SEIKO mechanical watch assembly. Although a bit too fast, I hope you enjoy as much as I did.

Thank you, Master Sakurada!

... To be continued next week for Part II

Ken

This message has been edited by AndrewD on 2011-04-08 05:27:48 This message has been edited by AndrewD on 2011-04-11 23:21:18

Next Article

© 2017 - WatchProZine