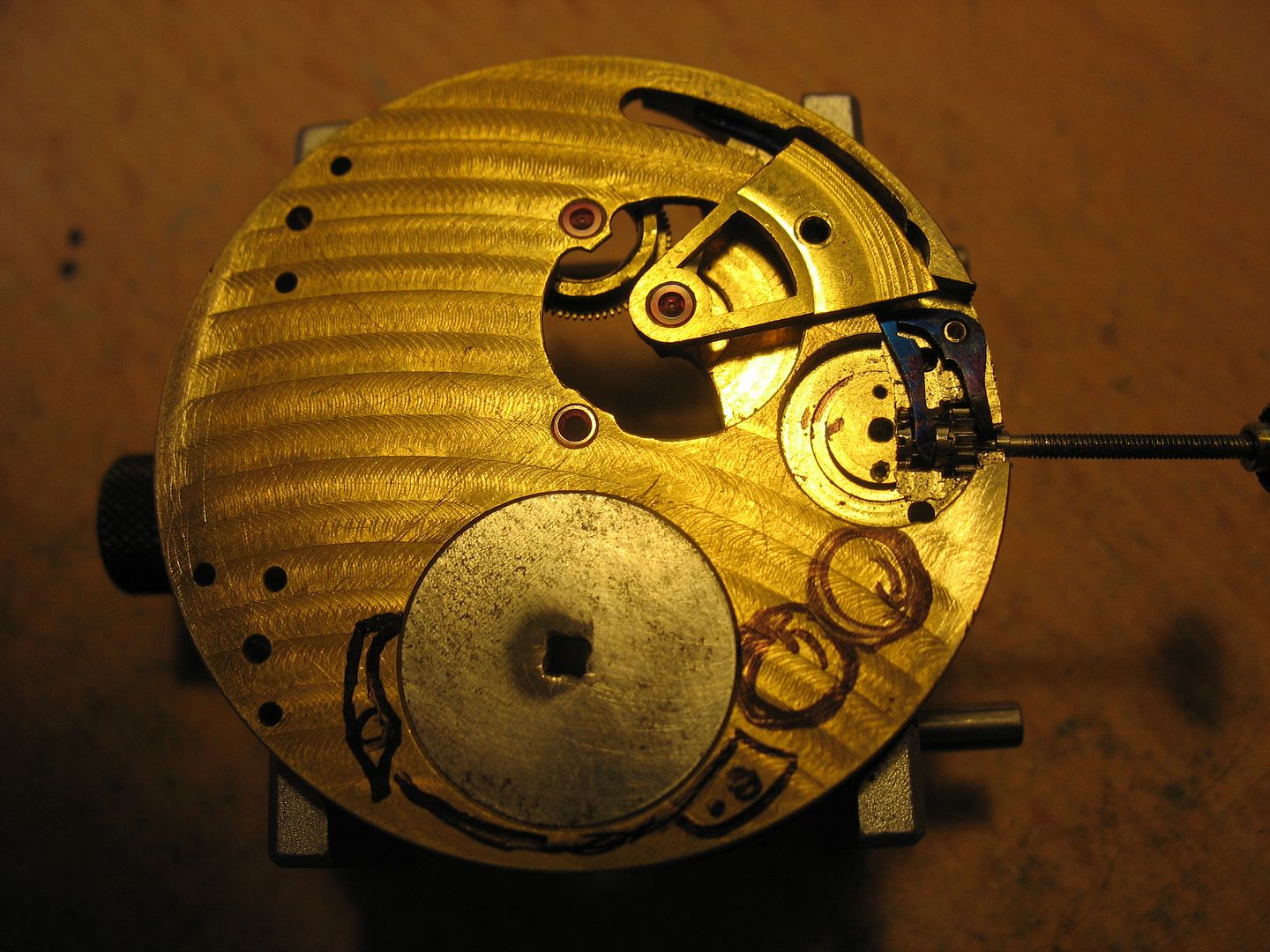

Tourbillon is one thing, but there are things that are more difficult...

Ondrej Berkus

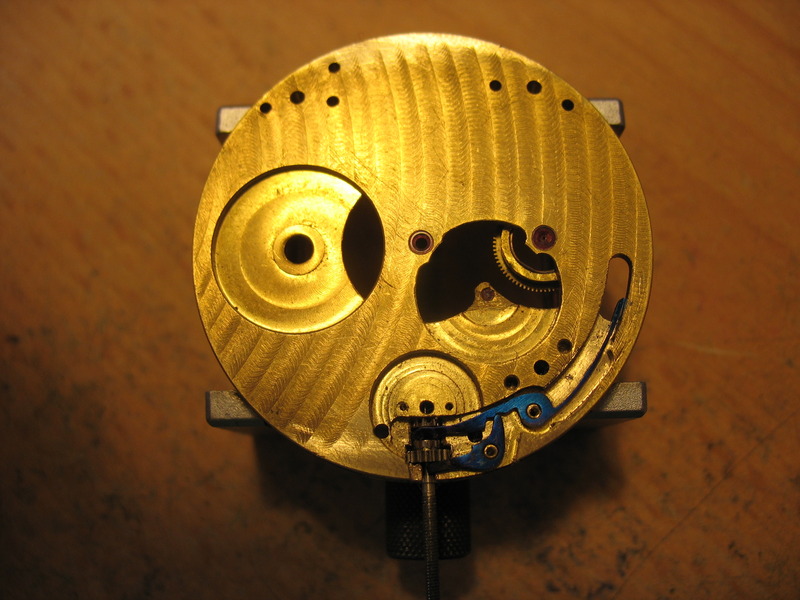

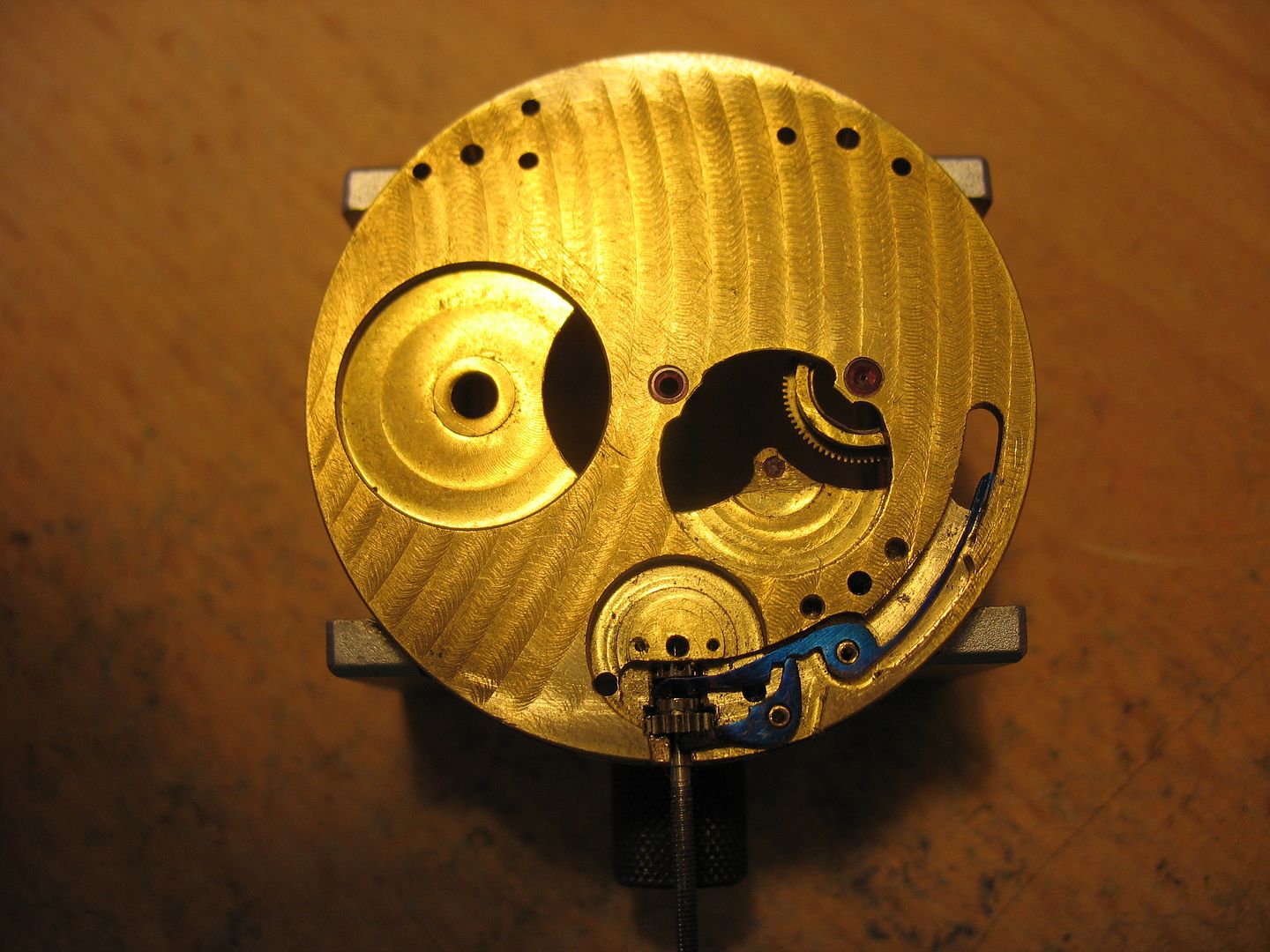

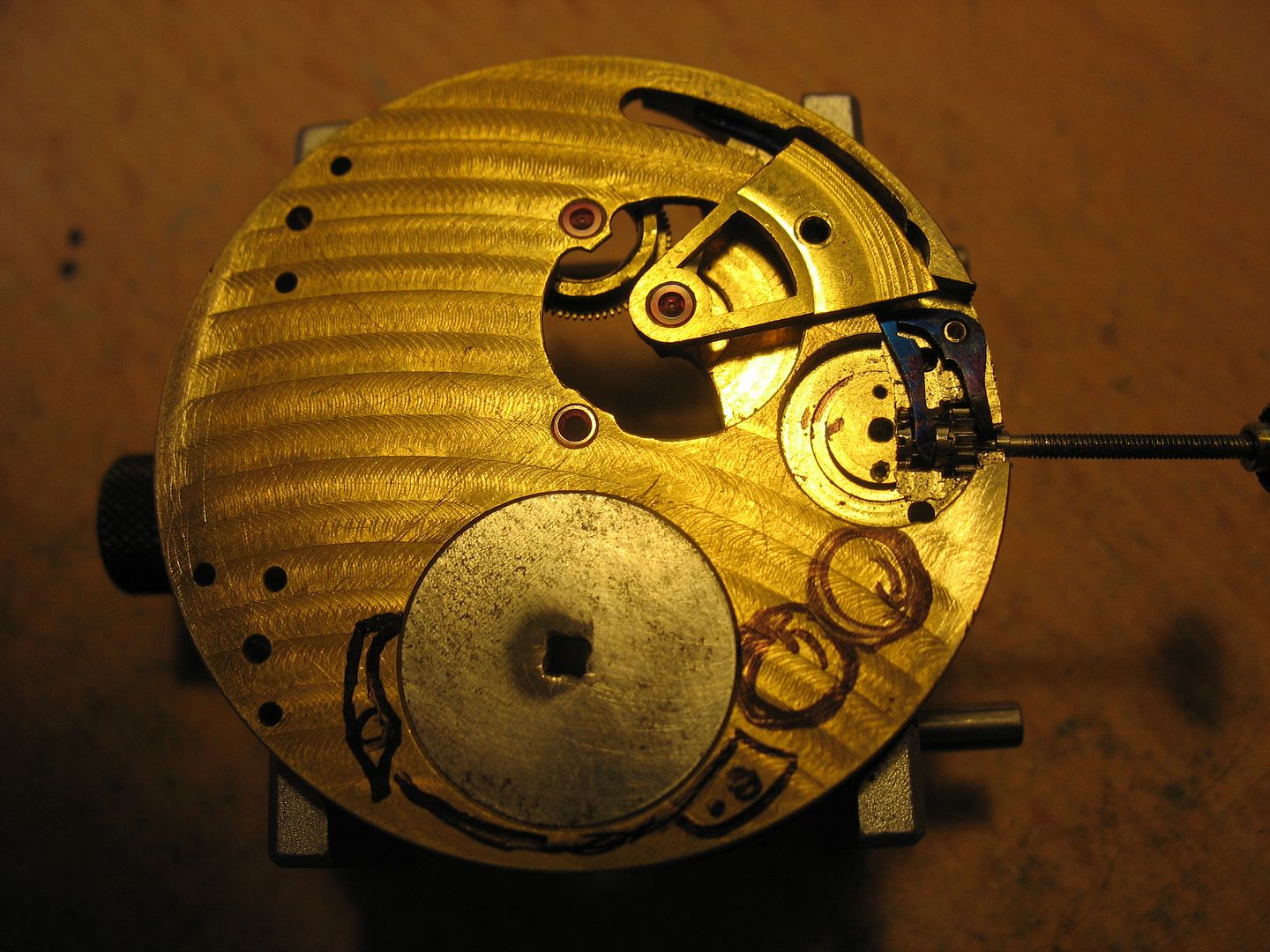

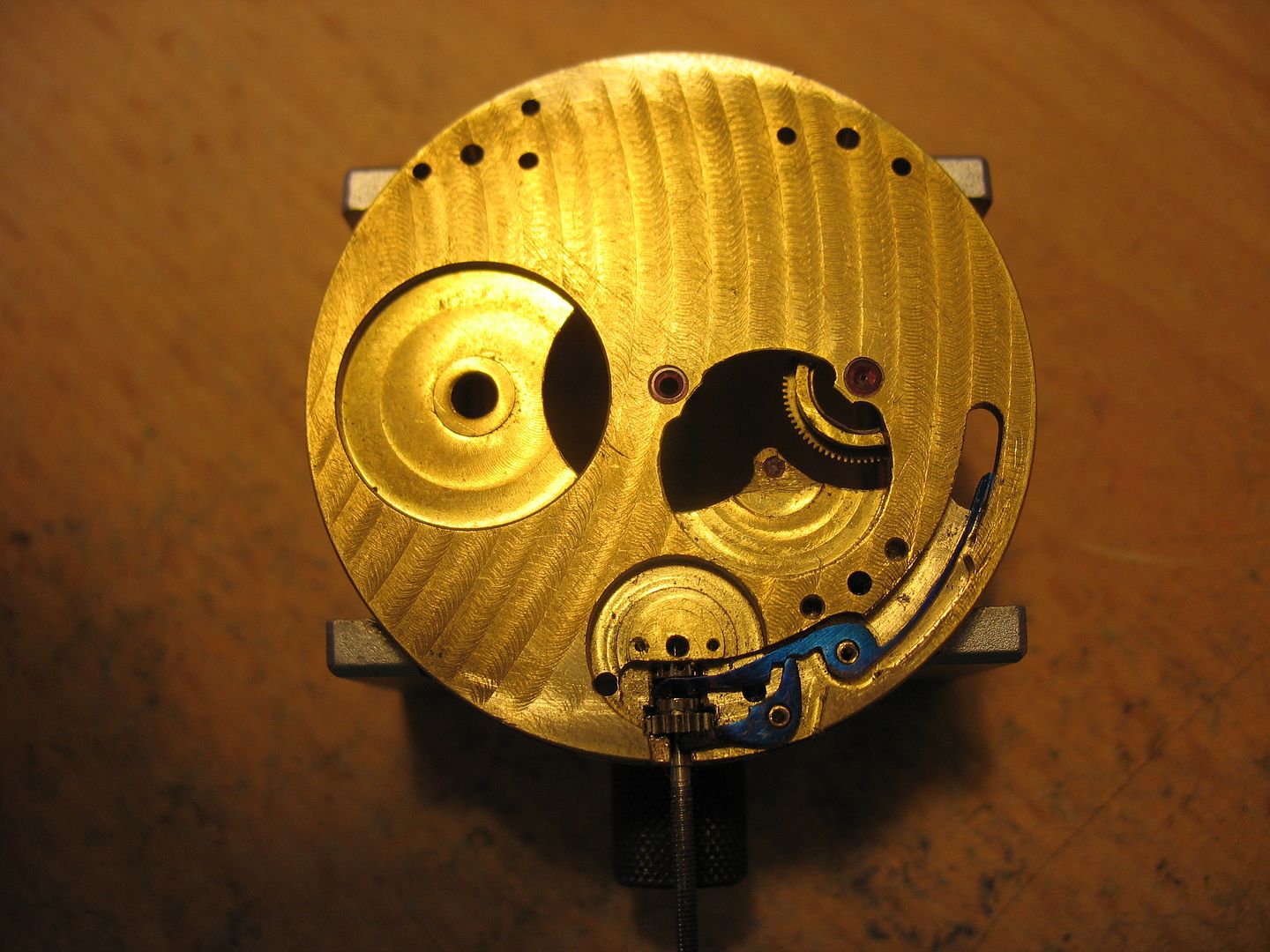

like making the keyless works - making those irregular pieces work and fit together is a lot more difficult than i ever thought. The tempering color is pretty though, after i polish them parts, i'm thinking of bluing them again. They should look nice against the nickel/rhodium plated plate and bridges... And i made a huge mistake in placing the intermediate wheel - i should have put it on the other side, now i have and ungainly look where one side of the movement is full and the other is empty... Plus the bridge for the wheel is hanging in the air... Oh well, one of the many things to note for the next time...

Also, although Mr. Daniels' watchmaking covers blanking and finishing the wheels, he doesn't mention how time consuming and nerve wrecking job it is. I mean wow, filing all the spokes to same shape, so everything is symetrical, finishing the insides and beveling everything.. Took me two days to finish one wheel, only to discover i damaged some of the teeth while filing to shape. Luckily, i had another wheel prepared, it took me only a day to finish, but due to the lack of skill, it looks appaling... I will have to do a lot better next time ( yes, the desire to see the movement finished, ticking and cased has taken over and i will not be making the wheels again ).

I guess one cannot be happy with everything everytime

Ondrej

Comments:

DonCorson October 5th, 2015-12:02

That is wonderful work Ondrej and we learn every day. I think that I made all the parts at least twice on my first watch, some parts even more. That is a part of the learning experience. The problem is that as you get more experience you get more critical too, so you end up remaking j...

Ondrej Berkus October 6th, 2015-01:02

Thank you for your kind words Mr. Corson. You are absolutely right about being more and more critical, it's probably a good thing in the shop but not so good thing in real life And i've gotten used to re-making parts. I think the fact that each part is made at leas...

Ornatus-Mundi October 6th, 2015-13:18

Ondrej, this is a wonderful example of inspiration taken by the grand masters... I'd love to do it as well if only I could - it must be nerver-wrecking at times but at the end - so satisfying. Do you have all the tools and machines 'at home'? Please keep us updated! Magnus

Ondrej Berkus October 7th, 2015-02:55

My shop is right across the yard, so yes, i got everything at home. Here's my shop and all tools in one of the posts. www.watchprosite.com Ondrej

0-10-4

Load More Comments

Next Article

DonCorson

A David Walter Double Pendulum Clock – Part 11, Making a Cock

DonCorson

Every week we are seeing more of David's work on his new double pendulum clock. This time we are being treated to a documentation of the making of a single part. These things don't just drop finished on the table. For those of you who didn't see the earlier installments of this series, you can catch up by looking here: - Installment 1 – Introduction and Cutting out the plates - Installment 2 – Making the Barrel - Installment 3 – The Suspension - Installment 4 – Invar Pendulum Parts - Installment 5 – Making ...

© 2017 - WatchProZine